4 Reasons Your Transition Between Innovation & Design Controls is Struggling

The transition between innovation stages and design controls is not simple to manage. It takes a lot of planning, preparation, and diligence to do well. Many life science organizations struggle in moving between these stages, and pinpointing the causes for this can be difficult. When evaluating your organization’s struggle with moving between innovation and design controls, there are four key areas to look at.

1. Inexperience

While there are a few large, well-established firms in life science industries today, the reality is that the majority of firms are small. Some estimates of the medical device market, for example, put the average business size at fewer than 50 employees. Consequently, many of these organizations lack the resources and industry experience of their larger counterparts.

When it comes to transitioning between innovation and design controls, this inexperience can be a serious issue. Skills and knowledge gaps in applying design controls to new ideas and solutions can adversely impact project timelines, product quality, and so on.

2. Processes & Procedures

The lack of thoroughly defined processes and procedures for the change between design controls and innovation is a common problem many life science organizations face. This can be influenced by inexperience, but is often a result of regulatory gray areas when it comes to innovation stages. Regulatory bodies like FDA and other agencies don’t require defined processes for translating activities such as journey mapping into design inputs, for example.

The lack of thoroughly defined processes and procedures for the change between design controls and innovation is a common problem many life science organizations face. This can be influenced by inexperience, but is often a result of regulatory gray areas when it comes to innovation stages. Regulatory bodies like FDA and other agencies don’t require defined processes for translating activities such as journey mapping into design inputs, for example.

Instead, their focus is on quality management activities that result in safe and effective products. While moving from innovation to design controls is a key area of concern when it comes to safety and effectiveness, it’s ultimately not something FDA and other bodies feel the need to address with regulations and guidance. Building processes and procedures around this part of the product development process is left up to manufacturers, and that gray area isn’t easy to deal with.

3. Traceability

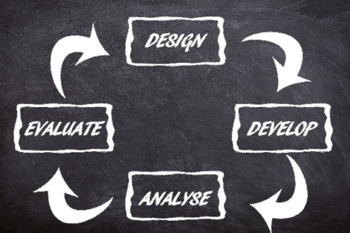

Transitioning between innovation and design controls is not a linear process, nor is it a solitary event; robust product development processes include mechanisms for moving back and forth between these crucial activities for product realization. Thus, there should be controls in place to make sure data is traceable throughout all your stages. Especially between design controls and innovation, your teams should be able to track how early stage insights were made, influenced your design inputs, and are altered as development progresses.

Transitioning between innovation and design controls is not a linear process, nor is it a solitary event; robust product development processes include mechanisms for moving back and forth between these crucial activities for product realization. Thus, there should be controls in place to make sure data is traceable throughout all your stages. Especially between design controls and innovation, your teams should be able to track how early stage insights were made, influenced your design inputs, and are altered as development progresses.

This sort of traceability is important because it reduces the likelihood of remediation or rework in later-stage development. There are clear timelines of how ideas and solutions were generated, translated into design inputs, and controlled throughout design controls stages. Rather than having to go back to the drawing board, this traceability can help your teams see why a design input was added in the first place, and how you could go about reconciling any resulting issues.

4. Stakeholder Management

One key concern for life science product development is ensuring stakeholder needs are met in the product design. While users and patients are the ones ultimately interacting with your product, many other stakeholders are involved in its overall life cycle—servicing professionals, regulators, company shareholders, etc. Managing all these voices in the design and development of your life science product is therefore a vital component of the realization process.

When it comes to the interchange between innovation and design controls, managing stakeholders has two levels of importance. First, making sure stakeholder needs are organized and prioritized helps in the formulation and incorporation of those needs into the product design. Second, as your teams go back and forth between these development stages, you can evaluate how resulting data from each will impact the other. For example, the inclusion of a new stakeholder need could impact product safety when worked on during design control stages; being able to see these concerns more concretely can avoid issues that can negatively impact later-stage development.

When it comes to the interchange between innovation and design controls, managing stakeholders has two levels of importance. First, making sure stakeholder needs are organized and prioritized helps in the formulation and incorporation of those needs into the product design. Second, as your teams go back and forth between these development stages, you can evaluate how resulting data from each will impact the other. For example, the inclusion of a new stakeholder need could impact product safety when worked on during design control stages; being able to see these concerns more concretely can avoid issues that can negatively impact later-stage development.

Innovation and Design Controls Work Together

Innovation and compliance aren’t opposites—in fact, when paired together and managed appropriately, they can lead to products that better meet consumer needs and improve patient outcomes. Keeping some of these common struggles in mind, therefore, can help ease the transition between these development stages, and help your team toward developing higher quality products. Being able to better manage stakeholders, traceability, team capacities and experience, and defined processes and procedures can help transform innovative ideas and solutions into realized products and services.

About Cognition Corporation

At Cognition, our goal is to provide medical device and pharmaceutical companies with collaborative solutions to the compliance problems they face every day, allowing the customer to focus on their products rather than the system used to create them. We know we are successful when our customers have seamlessly integrated a quality system, making day-to-day compliance effortless and freeing up resources to focus on product safety and efficacy.